- 07 2143 6088 / 07 2143 6099

- sales@aulglass.com.au

- 38-40 Lysaght Street, Acacia Ridge

As a proud 100% Australian-owned and operated company, we bring a legacy of excellence, innovation, and quality to every project we undertake.

From commercial skyscrapers to bespoke residential installations, our glass solutions reflect superior craftsmanship, advanced technology, and an unwavering commitment to meeting our customers’ needs.

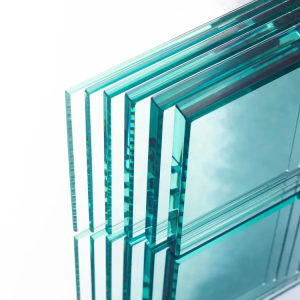

Our journey began with a mission: to deliver glass products that not only meet but exceed industry standards. Today, we stand as a leader in the glass manufacturing sector, known for our ability to combine traditional craftsmanship with cutting-edge technology. By continuously investing in the best equipment and adopting innovative practices, AUL Glass remains at the forefront of the industry, setting new benchmarks for quality, safety, and performance.

At AUL Glass, quality is more than a promise—it’s a guarantee. Every product we manufacture is meticulously crafted to meet Australian Standards AS1288 and AS/NZ2208, ensuring compliance with the highest safety and durability requirements. Whether you need glass for structural purposes, safety applications, or energy efficiency, you can trust AUL Glass to deliver products that are as reliable as they are refined.

Our rigorous quality assurance process includes thorough testing and inspection at every stage of production. This ensures that every sheet of glass we produce adheres to our strict standards, providing peace of mind to our clients and partners.

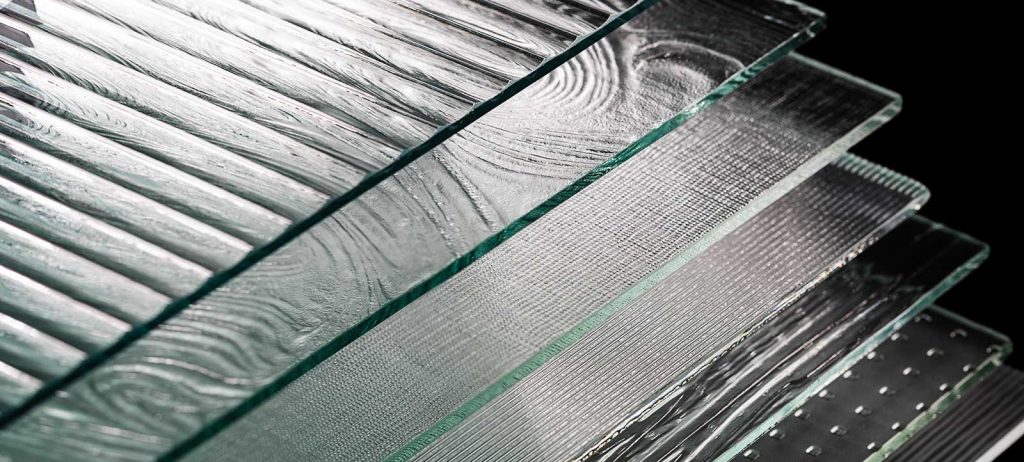

Glass plays a vital role in modern design and construction, offering versatility, functionality, and aesthetic appeal. At AUL Glass, we understand the transformative power of glass. From creating light-filled spaces to enhancing energy efficiency, our glass products are designed to elevate your projects in every way.

By leveraging the latest advancements in glass technology, we help our clients achieve their goals—whether it’s reducing energy costs, increasing safety, or making a bold architectural statement. Our team of experts works closely with you to identify the right glass solution for your specific needs, ensuring that every project is a success.

Our manufacturing process is meticulously designed to deliver high-quality glass solutions with precision and efficiency. Each stage is carefully managed by experienced professionals and supported by advanced machinery to ensure optimal results.

© 2022 All Rights Reserved.

All Rights Reserved – Copyright – 2025 – Website By SEQLDIT